Repmold: Revolutionizing the Future of Modern Manufacturing

Modern manufacturing is changing fast. Machines are getting smarter. Factories are getting smaller. Ideas are turning into products in days instead of months. At the center of this shift is Repmold. It is not just a new tool. It is a new way to think about making things.

TLDR: Repmold is transforming modern manufacturing by making production faster, cheaper, and more flexible. It blends advanced molding, automation, and smart software into one smooth system. Businesses can create custom products at scale without massive factories. The future of making things is simpler, smarter, and more efficient with Repmold.

What Is Repmold?

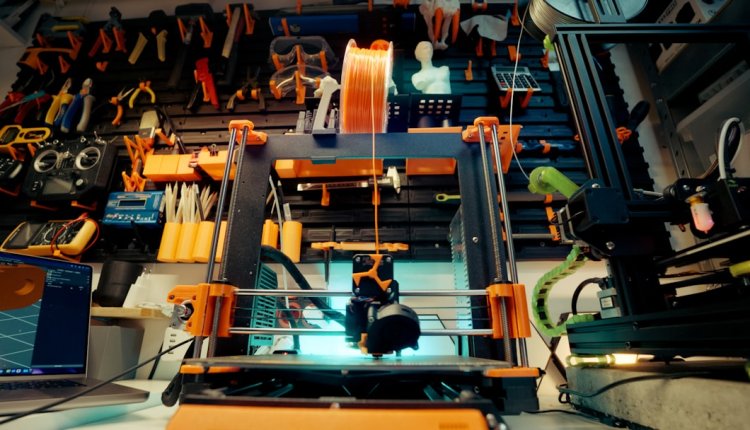

Repmold is a modern manufacturing system built around rapid replication and smart molding. It combines traditional molding techniques with digital design, automation, and real-time data.

Think of it as a bridge. On one side, you have classic factory methods. On the other side, you have futuristic tech like AI and smart robotics. Repmold connects the two.

This means:

- Faster prototyping

- Lower production costs

- High precision parts

- Easy customization

- Less material waste

In simple words, Repmold makes manufacturing feel less like heavy industry and more like smart design.

Why Traditional Manufacturing Needed a Change

Let’s be honest. Old manufacturing systems have problems.

They are:

- Expensive to set up

- Slow to adapt

- Resource heavy

- Hard to customize

If a company wants to change one small design detail, it can cost thousands of dollars. It may take weeks. Sometimes months.

The world today does not move that slowly.

Customers want personalization. Markets shift quickly. Supply chains get disrupted. Companies need flexibility.

That is where Repmold steps in.

How Repmold Works

Repmold uses digital models as its foundation. Everything starts on a screen. Engineers create a detailed 3D design. The software simulates stress, movement, and performance.

Once the design is ready, smart molding systems take over.

Unlike older molds, Repmold systems are adaptive. They can change shapes quickly. Some systems even adjust temperature and pressure automatically based on material feedback.

The process includes:

- Digital Design – AI-assisted modeling.

- Simulation Testing – Virtual stress analysis.

- Rapid Mold Creation – Fast, automated setup.

- Smart Production – Sensors monitor every step.

- Continuous Optimization – Data improves future runs.

This tight loop between design and production removes waste. It saves time. It improves quality.

The Power of Speed

Speed changes everything.

With traditional systems, launching a new product could take six months or more. Repmold reduces that to weeks. Sometimes even days for small runs.

Why does this matter?

- Startups can move fast.

- Large brands can test ideas quickly.

- Custom products become realistic.

Imagine designing a new phone accessory today and shipping it next week. That is the kind of speed Repmold enables.

Customization at Scale

Mass production once meant sameness. Every item looked identical.

Repmold changes that.

Because it is digitally driven, small changes in design do not require massive retooling. A company can tweak size, color, shape, or features with minimal cost impact.

This is called mass customization.

For example:

- Medical devices tailored to individual patients

- Automotive parts adjusted for different models

- Consumer products personalized with names or features

Customers feel special. Companies stay efficient.

Smarter Factories, Smaller Footprints

Traditional factories need large spaces and huge equipment lines.

Repmold systems are modular. They are compact. They can fit into smaller facilities.

This leads to:

- Lower energy use

- Reduced real estate costs

- Decentralized production

Instead of one giant factory serving the entire world, companies can build several smaller smart facilities closer to customers.

This reduces shipping time. It cuts carbon emissions. It strengthens supply chains.

Sustainability Matters

Manufacturing has long been criticized for pollution and waste.

Repmold addresses that directly.

It uses:

- Precision material control

- Recyclable mold components

- Energy efficient heating systems

- Real-time waste monitoring

Because simulations predict material needs accurately, overproduction drops. Scrap materials shrink. Companies use only what they need.

That is good for business. And good for the planet.

Data Is the Secret Weapon

Repmold thrives on data.

Sensors measure temperature, pressure, humidity, and cycle times. AI systems analyze the numbers instantly.

If something starts to drift out of range, the system corrects itself.

This leads to:

- Higher consistency

- Fewer defects

- Predictive maintenance

Machines even know when they need service before a breakdown happens.

Less downtime means more reliability. More reliability means happier customers.

Who Benefits from Repmold?

The short answer? Almost everyone.

Startups benefit from low setup costs.

Large enterprises benefit from flexibility.

Medical companies benefit from precision.

Automotive brands benefit from rapid iteration.

Even education and research institutions gain. Students can design and produce real-world parts quickly. Ideas move from classroom to product in record time.

Real-World Applications

Repmold is already influencing multiple industries.

In healthcare, it helps create patient-specific implants. Each piece fits better. Recovery improves.

Image not found in postmetaIn automotive manufacturing, engineers use it for lightweight components. Cars become more fuel efficient.

In consumer electronics, companies prototype new cases and frames faster than ever. Products reach market sooner.

Even aerospace companies are exploring how Repmold systems can support lighter and stronger components.

The Human Side of Automation

Some people worry about automation. They fear job loss.

But Repmold does not remove humans. It changes their roles.

Instead of repetitive manual tasks, workers focus on:

- Design innovation

- System oversight

- Data analysis

- Quality control

This creates demand for skilled technicians and engineers. It encourages training and education.

The factory worker becomes a tech operator. A problem solver. A digital craftsman.

Cost Efficiency Without Sacrificing Quality

Lower cost usually means lower quality. Not here.

Repmold reduces cost through efficiency, not shortcuts.

It eliminates:

- Excess inventory

- Long downtime

- Repetitive errors

- Transportation waste

At the same time, real-time monitoring improves precision.

The result is a rare combination: better products at lower cost.

The Role of Artificial Intelligence

AI plays a massive role in Repmold systems.

It assists in:

- Optimizing mold shapes

- Predicting stress points

- Automating design suggestions

- Forecasting demand

AI turns guesswork into science.

Designers can test ten variations in software before creating a single physical mold. That saves time and money.

The smarter the system becomes, the better it performs.

Challenges to Consider

No revolution is perfect.

Repmold systems require:

- Initial investment

- Training programs

- Cybersecurity protection

Since operations rely heavily on digital systems, data security is crucial. Companies must protect designs and production information.

However, as adoption grows, costs are decreasing. Training resources are improving. Security technologies are advancing.

The Future of Repmold

The future looks bright.

We may soon see:

- Fully autonomous micro factories

- Localized production hubs in every major city

- Real-time global collaboration between engineers

- Zero-waste production targets

Imagine ordering a custom product online. A nearby smart factory produces it the same day. It arrives at your doorstep tomorrow.

That is not science fiction. That is the direction Repmold is heading.

A New Manufacturing Mindset

Repmold is more than a tool. It represents a mindset shift.

It says manufacturing does not have to be slow. It does not have to be rigid. It does not have to be wasteful.

It can be:

- Agile

- Smart

- Efficient

- Personalized

Modern manufacturing is becoming creative again. Engineers can experiment. Designers can dream bigger. Companies can respond faster.

Repmold stands at the center of this transformation.

The factories of tomorrow will not just build products. They will build possibilities.

And that is a revolution worth watching.

Comments are closed, but trackbacks and pingbacks are open.